The industrial supply landscape is often a battle of having the right solution available when your customer needs it. Do this well and your customer will boost your service score. The result is you get closer to being a true partner and not just a commodity supplier.

So, where can suppliers use predictive analytics, within their CRM, to anticipate customer behaviors leading to successful transactions and gain a competitive advantage?

What are predictive analytics?

Predictive analytics answers the questions of what just happened and why? Taking it a step further, we need to know how we make it happen again. Manufacturers, distributors, and reps can create supply chain value using analytics to predict customer behavior.

Perhaps the low hanging fruit is with inventory levels using operational analytics for inventory planning including stock levels, low order point, etc. This can be studied for all services and product lines, but it can be very useful to do this by customer. “A” customers expect excellent lead times. This analysis can justify the quick-turn products and solutions they require, and even lower the risk of onsite consignment stocking programs.

By using historical data along with current trends to make predictions about future outcomes, sellers can anticipate their customers’ needs and provide custom solutions. This can help build trust and loyalty, and ultimately drive sales as a trusted partner.

In a 2023 Selltis LLC survey of 6,000 manufacturing reps and distributors, of those using CRM just 62% utilize any analytics to predict client buying behavior. This is an opportunity for the 38% who do not utilize this function. Here are some ways in which predictive analytics can help build better outcomes between industrial buyers and sellers.

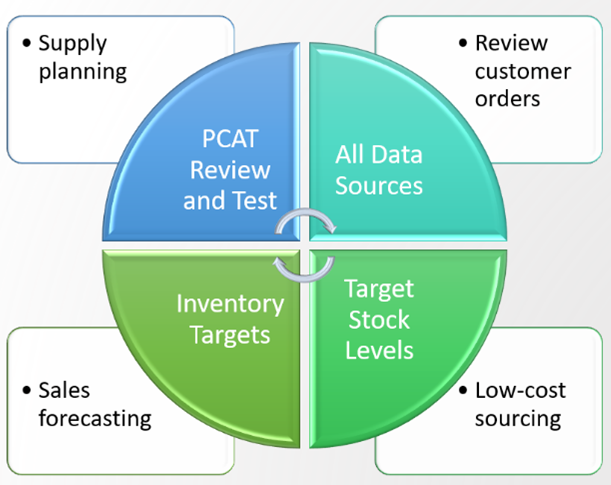

Anticipate Customer Needs with Better Inventory Management: This is an easy one. Using predictive analytics, sellers anticipate when a customer is likely to need a particular product or service. In the industrial sector we can analyze everything from custom solutions, standard products to consumables. This can help sellers proactively offer improved lead times creating a better customer experience. Analyzing MRO orders vs. small or large project spikes can help determine usage and set smart stocking levels.

Targeted Recommendations: Predictive analytics can also help sellers make targeted recommendations to their customers based on their past behavior and preferences. This can help build trust and demonstrate that the seller understands their customers’ needs. Analyzing the usage of consumables, distributors can predict trends towards the correct metallurgy or range for in situ type instrumentation, for example.

Customized Solutions: By using predictive analytics to analyze customer data, sellers can develop customized solutions that meet the needs of their customers. This can help build loyalty and improve customer satisfaction. A paper mill requiring a hot standby controller or a particular mag meter for use in a digester blow line could be available 24X7 at the rep location until needed. This reduces customer inventory costs and allows a higher margin solution to be readily available.

Overall predictive analytics can help sellers build better relationships with their industrial buyers by anticipating their needs, providing targeted recommendations, developing customized solutions, and improving inventory management. By leveraging the power of predictive analytics, sellers can improve their supplier score along with driving revenue growth.

Where to get predictive analytics tools?

Many ERP and CRM solutions offer a basic analytics package including Salesforce, NetSuite and QuickBooks. You can also use bolt-ons from Zoho, Fathom, Syft, Google Analytics and others.

Dashboards are needed to display the data in usable packets to drive smart decisions and actions. With 25 years’ experience, SalesProcess360 offers field-proven tools and templates to create role-based displays specific to industrial manufacturing, rep and distribution clients.

SalesProcess360 delivers ROI by focusing on three key areas needed for successful CRM deployment. Areas include Design Assurance, Project Execution Assurance and Onboarding Assurance.

For more information, reach out and begin the engagement process. Let us show you our portfolio of field-proven tools and how we have helped similar clients achieve outstanding ROI from their CRM investment.